Search This Supplers Products:GlasswareGlass Coffee SetGlass CupGlass TeapotGlass jarGlass Perfume Bottle

How to make glass?-9 steps to make glass by furnace or kiln

9 steps to make glass

Step1

Obtain silica sand. Also called quartz sand, silica sand is the primary ingredient in making glass. Glass without iron impurities is sought for clear glass pieces, as the iron will cause the glass to appear greenish when present.

Wear a face mask if handling extremely fine-grain silica sand. If inhaled, it can irritate the throat and lungs.Silica sand is available from online retailers. It is fairly cheap - small quantities shouldn't cost more than 20 dollars. If you want to operate on an industrial scale, specialty retailers can offer competitive rates on large orders - sometimes lower than $100 per ton.If it is not possible to find sand sufficiently free of iron impurities, their tinting effect can be countered by adding small amounts of manganese dioxide. Or, if you want greenish glass, leave the iron in!

Step2

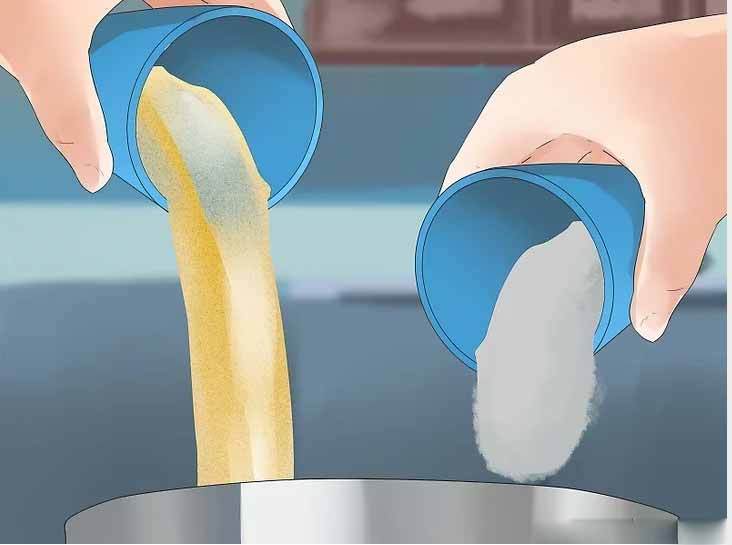

Add sodium carbonate and calcium oxide to the sand. Sodium carbonate (commonly called washing soda) lowers the temperature necessary to make glass commercially. However, it permits water to pass through the glass, so calcium oxide, or lime, is added to negate this property. Oxides of magnesium and/or aluminum may also be added to make the glass more durable. Generally, these additives take up no more than 26 to 30 percent of the glass mixture.

Step3

Add other chemicals, depending on the glass's intended purpose. The most common addition for decorative glass is lead oxide, which provides the sparkle in crystal glassware, as well as the softness to make it easier to cut and also lowers the melting point. Eyeglass lenses may contain lanthanum oxide because of its refractive properties, while iron helps glass absorb heat.

Lead crystal can contain up to 33 percent lead oxide; however, the more lead oxide, the more skill required to shape the molten glass, so many lead crystal makers opt for less lead content.

Step4

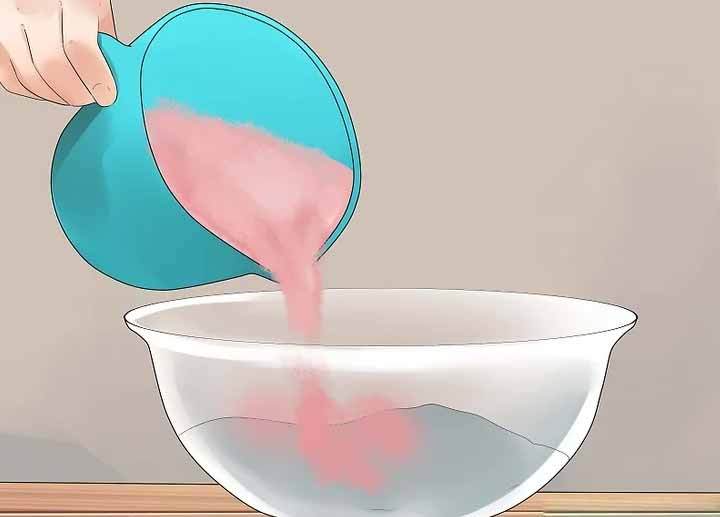

Add chemicals to produce a desired color in the glass, if any. As noted above, iron impurities in quartz sand make glass made with it appear greenish, so iron oxide is added to increase the greenish tint, as is copper oxide. Sulfur compounds produce a yellowish, amber, brownish or even blackish tint, depending on how much carbon or iron is also added to the mixture.

Step5

Place the mixture in a good heat-resistant crucible or holder. The container should be able to withstand the extremely high temperatures within the kiln - depending on your additives, your glass mixture may melt at a range of temperatures between 1,500 and 2,500 degrees Celsius. Your container should also be easily grasped with metal hooks and poles.

Step6

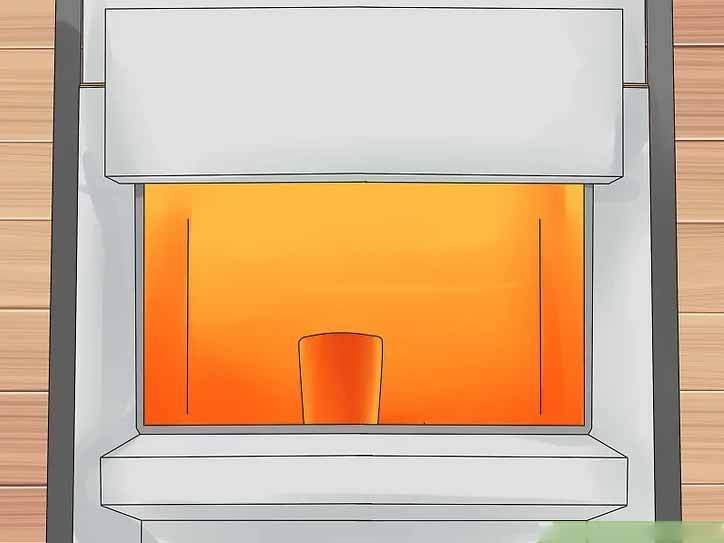

Melt the mixture into a liquid. For commercial silica glass, this is done in a gas-fired furnace, while specialty glasses may be created using an electric melter, pot furnace or kiln.

Quartz sand without additives becomes glass at a temperature of 2,300 degrees Celsius (4,172 degrees Fahrenheit). Adding sodium carbonate (soda) reduces the temperature needed to make glass to 1,500 degrees Celsius (2,732 degrees Fahrenheit).

Step7

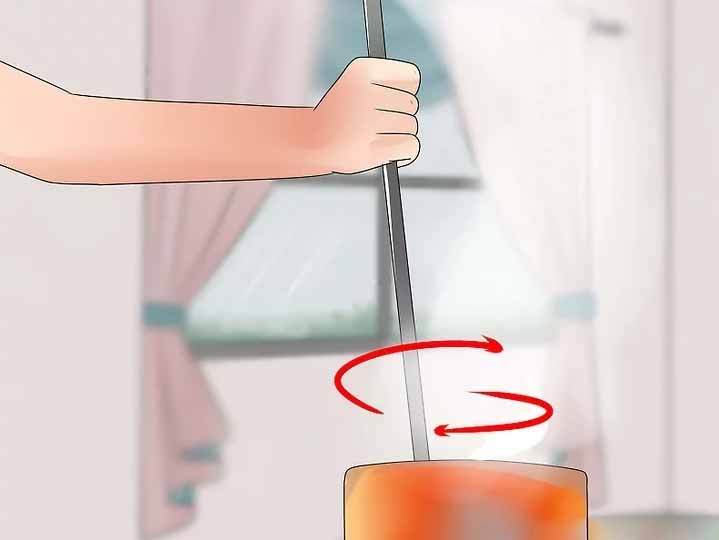

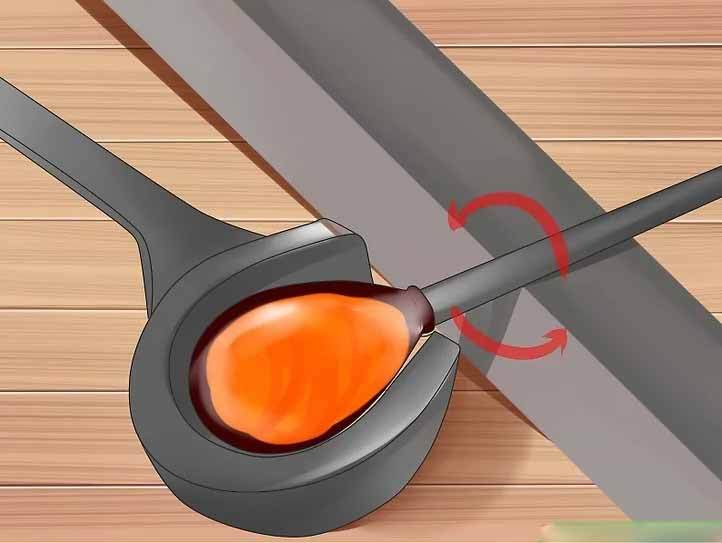

Homogenize and remove bubbles from the molten glass. This means stirring the mixture to a consistent thickness and adding chemicals such as sodium sulfate, sodium chloride or antimony oxide.

Step8

Shape the molten glass. Shaping the glass can be done in one of several ways:

The molten glass can be poured into a mold and let cool. This method was used by the Egyptians, and it is also how many lenses are created today.

A large amount of molten glass can be gathered at the end of a hollow tube, which is then blown into while the tube is turned. The glass is shaped by the air entering the tube, gravity pulling on the molten glass and whatever tools the glassblower uses to work the molten glass.

The molten glass can be poured into a bath of molten tin for support and blasted with pressurized nitrogen to shape and polish it. Glass made by this method is called float glass, and it is how glass panes have been made since the 1950s.

Step9

Slowly cool the glass in a kiln. This process is called annealing, and it removes any stress points that may have formed in the glass during cooling. Glass that has not been annealed is significantly weaker. Once this process is completed, the glass can then be coated, laminated or otherwise treated to improve its strength and durability.

The precise temperature for annealing can vary based on the precise composition of the glass from as low as 750 degrees Fahrenheit to as high as 1000 degrees Fahrenheit. The rate at which the glass must cool may also change - generally, larger pieces of glass must cool more slowly than smaller pieces. Research proper annealing methods before beginning.

A related process is tempering, in which shaped and polished glass is placed in an oven heated to at least 600 degrees Celsius (1,112 degrees Fahrenheit) and then quick-cooled ("quenched") with blasts of air at high pressure. Annealed glass breaks into shards at 6,000 pounds per square inch (psi), while tempered glass breaks into small pieces at no less than 10,000 psi and usually at around 24,000 psi.