Search This Supplers Products:GlasswareGlass Coffee SetGlass CupGlass TeapotGlass jarGlass Perfume Bottle

How to blow glass?

How to blow glass?

Glassblowing is the art of creating glass sculptures by manipulating molten glass in a very hot furnace. It is a fun way to express your creativity and try working with a new material. The most common and accessible type of glassblowing is called offhand, where you heat and shape the glass on the end of a hollow pipe. Blowing glass requires working closely with heat and glass, so make sure you take all the necessary precautions before you roll, blow, and shape the glass.

1.Gathering the Glass on the Pipe

Step1

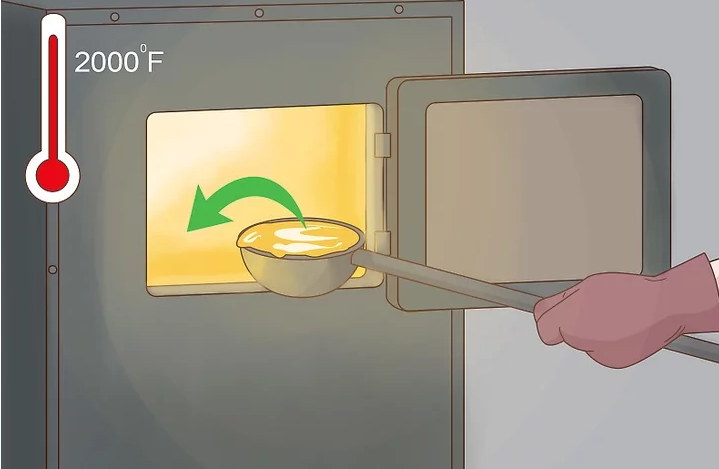

Place the molten glass in the furnace. Use heat resistant gloves to place the molten glass in the furnace. The furnace should be heated to 2,000 °F (1,090 °C) to melt the glass.

Heating and melting the glass will make it more malleable and easier to gather on the blowpipe.

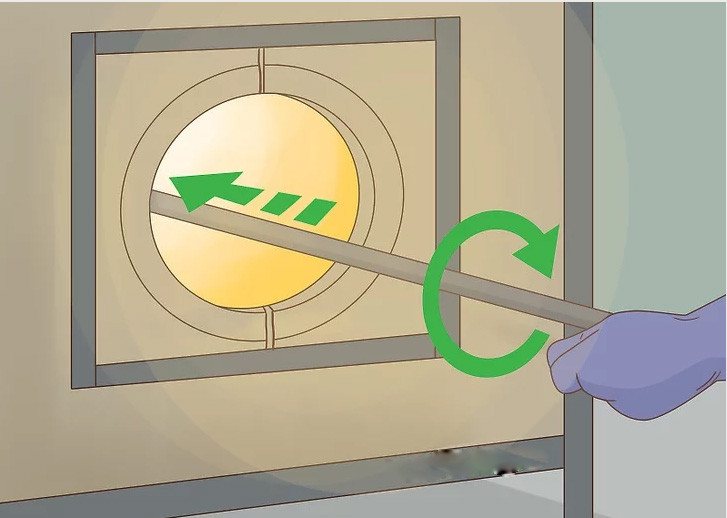

Step2

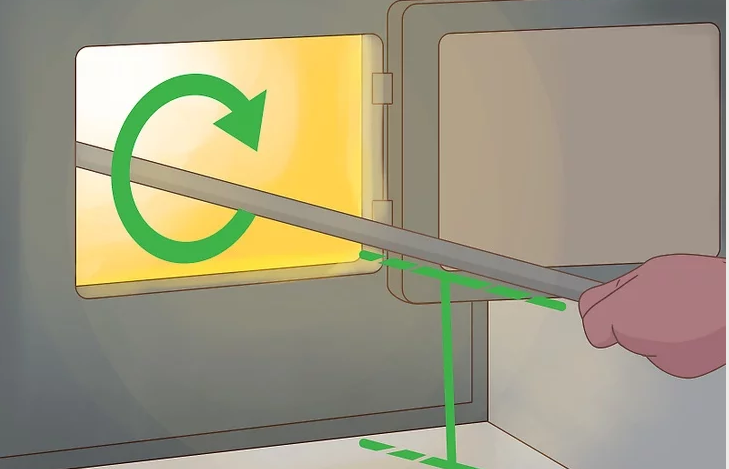

Put the pipe in furnace and gather the glass. Put one end of the pipe in the furnace, holding the pipe straight. You may need an assistant to open the door of the furnace for you so you can put in the pipe. Then, roll the pipe around in the furnace to gather the glass. You want to get as much of the glass on the pipe as you can so you have a lot to work with.

You can try to open the furnace door yourself if you do not have someone to assist you, but it may be tricky to do if you are beginner glassblower.

Step3

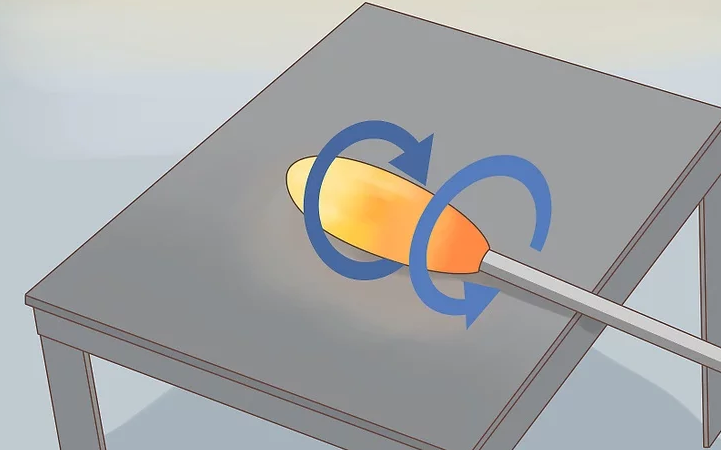

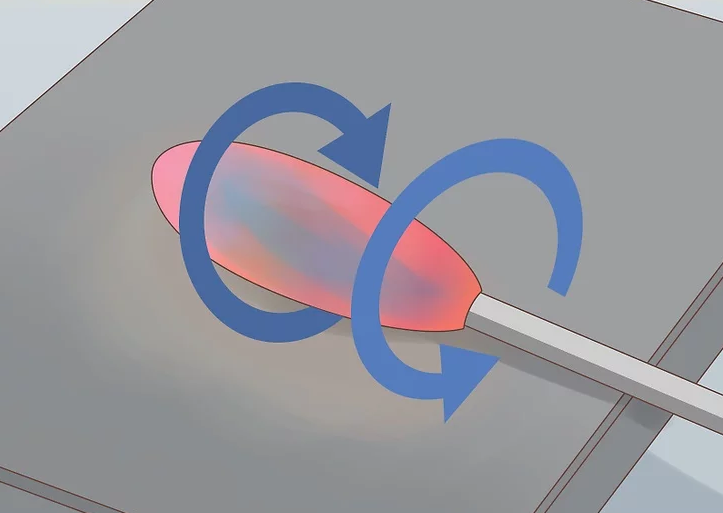

Roll the glass on the marver to form a cylinder shape. Carry the glass on the pipe to the marver. Roll it on the marver in a continuous, round motion. The marver will help to distribute the heat on the glass evenly and allow you to shape the glass into a cylinder that is symmetrical.

Step4

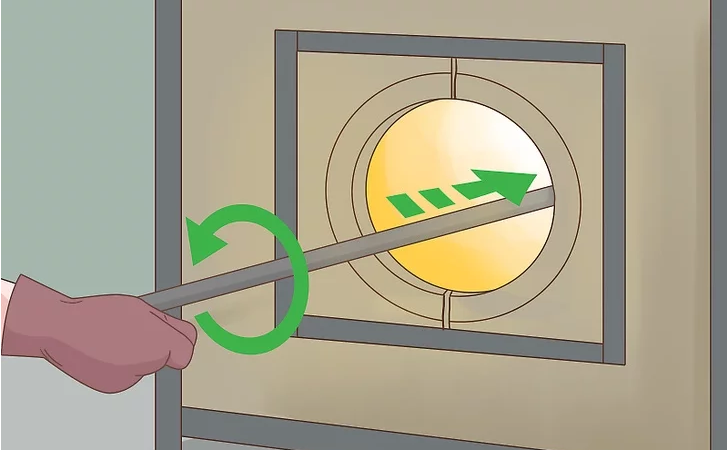

Put the glass in the crucible, or glory hole, and turn it several times. Roll the glass in the heat of the glory hole so it stays hot. This will ensure it does not become too hard or tough for blowing.

Step5

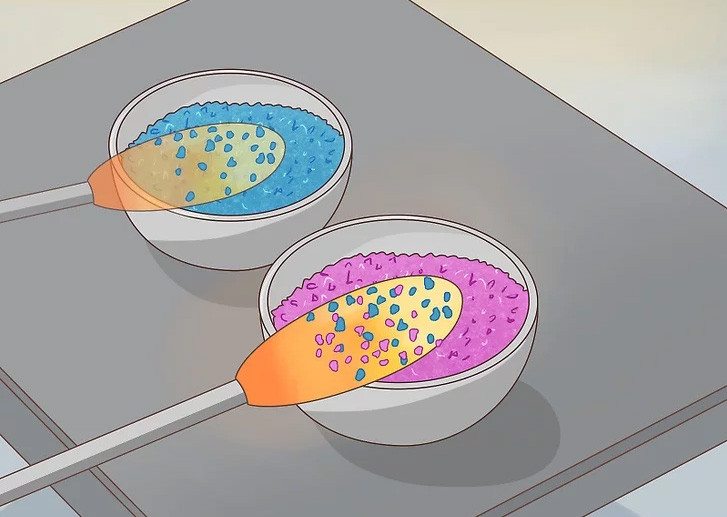

Dip the glass into crushed colored glass to add color. If you want your blown glass piece to have flecks of color in it, carefully dip it in a steel bowl of crushed glass. Add one layer of crushed glass to each side of the rounded glass by dipping it once in each color.

Once you’ve dipped the glass, put it back in the crucible and turn it several times so the crushed glass melts.

Step6

Roll it on the marver again. Try to get it to form the shape of a bullet. Keep the sides even and rounded so the glass is easier to blow.

2.Blowing the Glass

Step1

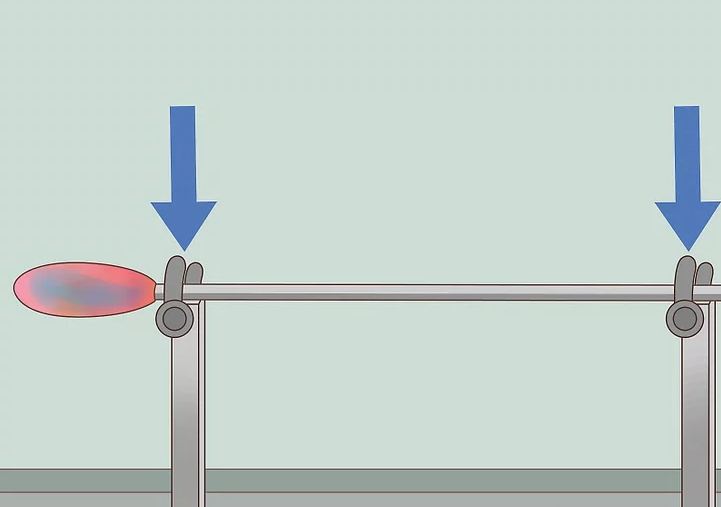

Place the pipe on a stand. Use a steel stand that can hold the pipe securely. This will make blowing into the pipe easier.

If you do not have access to a stand, you can blow the pipe by holding it just above the marver. However, it may be tricky for you to hold the pipe and blow into it at the same time, especially if you are a beginner.

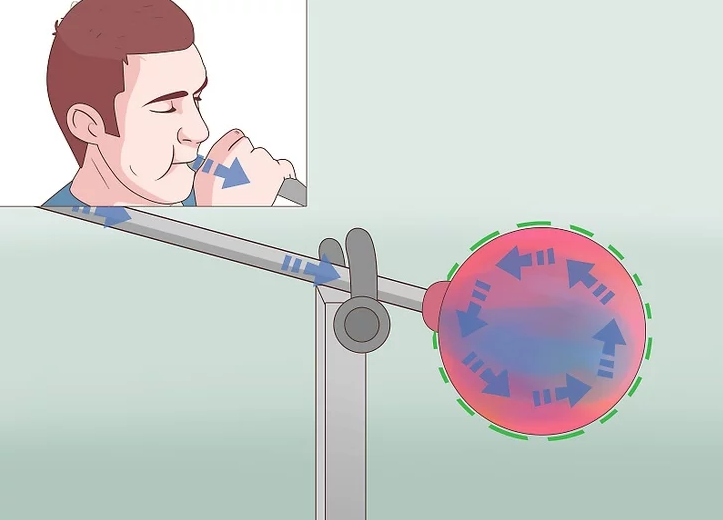

Step2

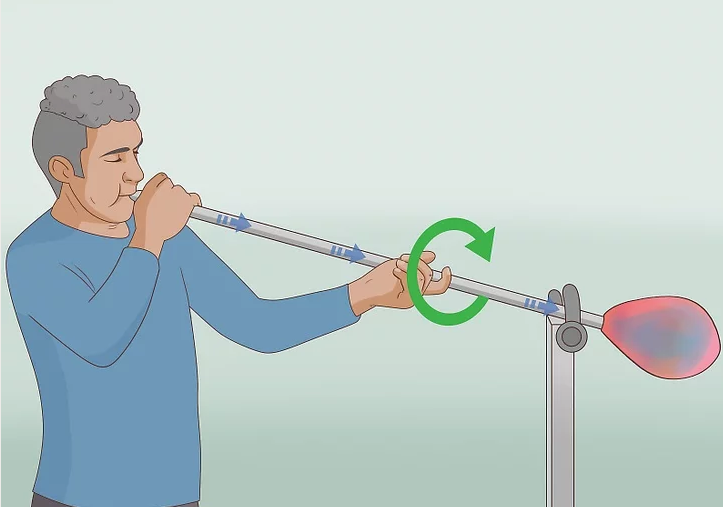

Blow into the the pipe and roll it at the same time. Let out deep breaths into the pipe to blow air into the glass. Turn the pipe as you blow into it so the air is evenly dispersed. Blow into the glass continuously with even breathes for 10-15 seconds.

Do not blow into the glass for too long, as you do not want it to become too cool or lose too much heat. Blow into it for 10-15 second intervals so it stays hot.

Step3

Return the glass back to the crucible to keep it hot. Turn pipe several times as the glass heats up in the crucible.

Step4

Repeat the process until the glass is the size you want. Continue blowing into the end of the pipe to expand the glass. Always turn it as you blow. Then, return it to the crucible and turn it several times. Blow and heat the glass until you have blown the glass to the size and shape you want.

3.Cooling the Glass

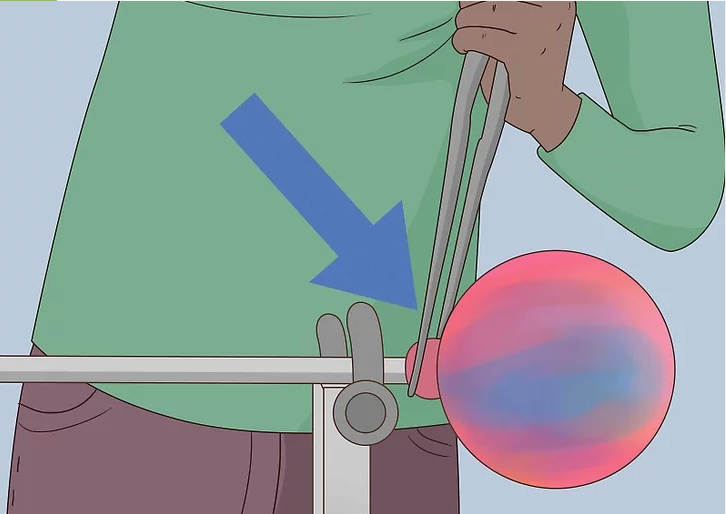

Step1

Have an assistant cut the bottom of the blown glass with steel tweezers. The assistant will run the tweezers, called jacks, around the bottom of the blown glass as you turn the pipe. This will help to cut the bottom and loosen the glass so it can come off.

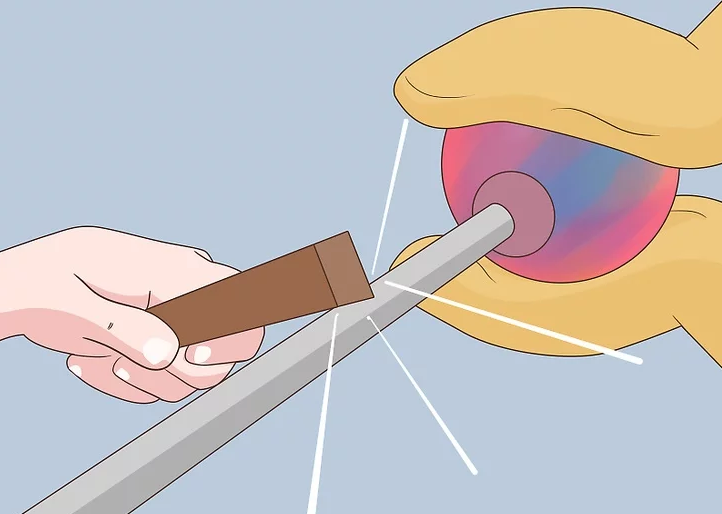

Step2

Tap the pipe to remove the blown glass. Use a wooden block to hit the pipe once so the blown glass comes off the pipe where the glass has been cut. Make sure your assistant is ready, wearing heat resistant gloves, to catch the blown glass when it comes off the pipe.

Try to hit the pipe only once with a hard and firm whack. Doing it more than once can cause the blown glass to crack or break.

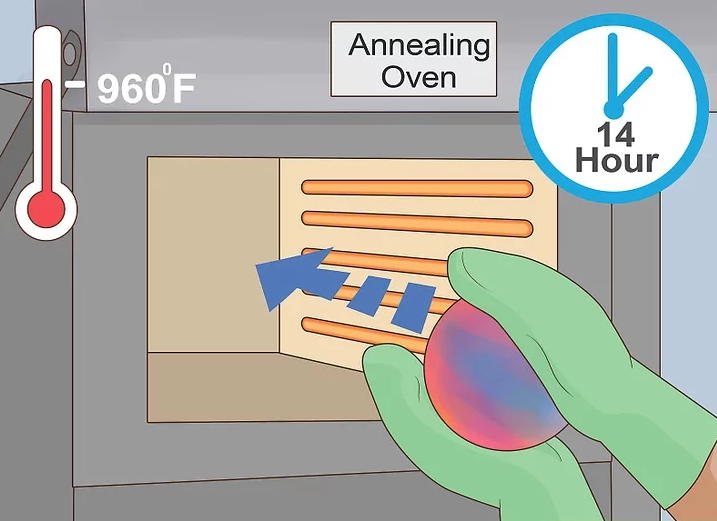

Step3

Transfer the blown glass to an annealing oven. The annealing oven should be kept at 960 °F (516 °C). Wearing heat resistant gloves, put the blown glass in the oven. The oven should then be cooled down over 14 hours to room temperature. The slow cool down period will prevent the blown glass from cracking or breaking.

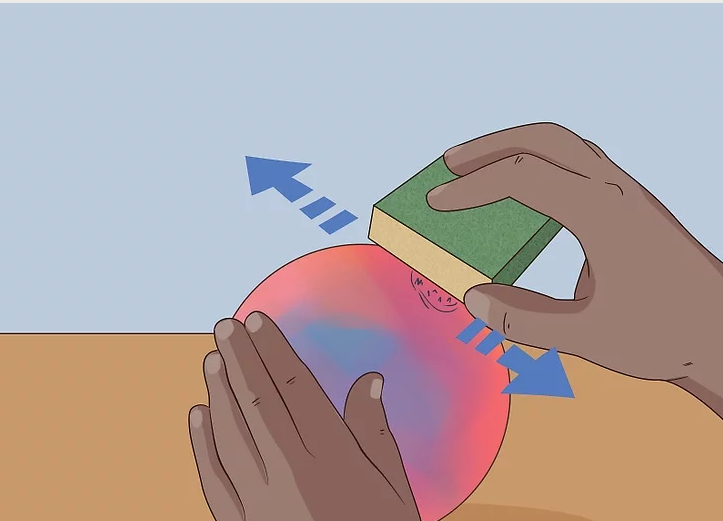

Step4

Remove any sharp edges on the finished piece. Take the blown glass out of the annealing oven after 14 hours. Inspect it for any sharp edges, especially on the bottom. Use a grinding block to carefully smooth them out.