Search This Supplers Products:GlasswareGlass Coffee SetGlass CupGlass TeapotGlass jarGlass Perfume Bottle

Introduction to high borosilicate glass:

time2023/09/17

- High borosilicate glass is a kind of glass with enhanced fire resistance.

Introduction to high borosilicate glass:

High borosilicate glass is a kind of glass with enhanced fire resistance.

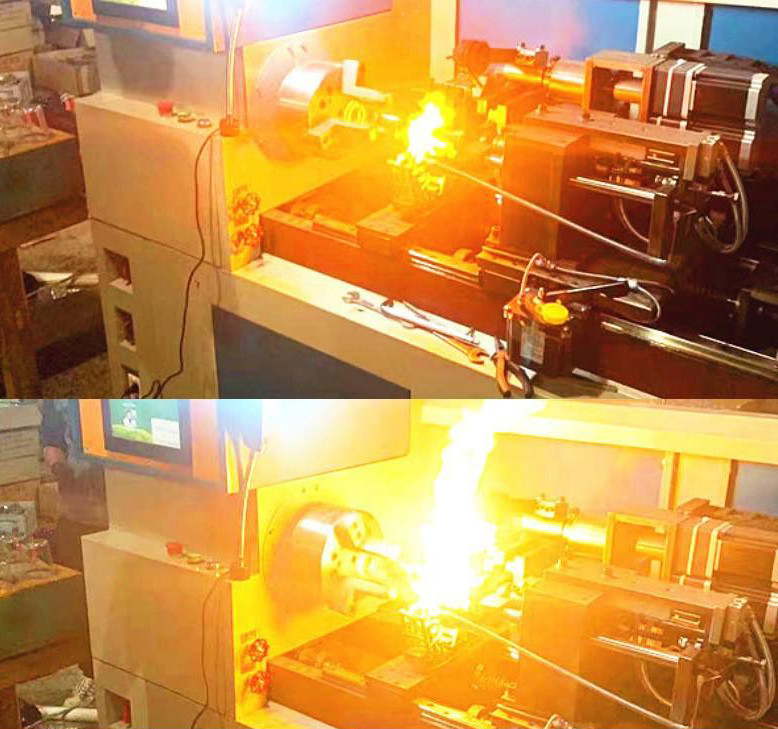

The manufacturing process involves adding glaze water glass sand, soda water and lime. Since high borosilicate glass has a higher melting temperature than ordinary silicate glass, some new technologies and processes are required during the manufacturing process.

Manufacturing process

Borosilicate glass is made by adding boron to traditional glass making glazes of water glass sand, soda water and ground lime. Since borosilicate glass melts at higher temperatures than ordinary silicate glass, some new technologies are needed to enable industrial production.

Wide range of applications

High borosilicate glass has good fire resistance and high physical strength. Compared with ordinary glass, it has no toxic side effects. Its mechanical properties, thermal stability, water resistance, alkali resistance, acid resistance and other properties are greatly improved. Therefore, it can be widely used in various fields such as chemical industry, aerospace, military, family, hospital, etc. It can be made into lamps, tableware, standard plates, telescope pieces, washing machine observation holes, microwave oven dishes, solar water heaters and other products, and has good promotion value and social benefit.

High borosilicate glass is an important material used to make highly durable glass instruments such as beakers and test tubes. Of course, its applications are far more than these. Other applications include vacuum tubes, aquarium heaters, flashlight lenses, professional lighters, pipes, glass ball art, high-quality beverage glassware, solar thermal utilization vacuum tubes, etc., at the same time , has also been used in the aerospace field. For example, the insulation tiles of the space shuttle are also coated with high borosilicate glass.

High borosilicate glass has good fire resistance and high physical strength. Compared with ordinary glass, it has no toxic side effects. Its mechanical properties, thermal stability, water resistance, alkali resistance, acid resistance and other properties are greatly improved. Therefore, it can be widely used in various fields such as chemical industry, aerospace, military, family, hospital, etc. It can be made into lamps, tableware, standard plates, telescope pieces, washing machine observation holes, microwave oven dishes, solar water heaters and other products, and has good promotion value and social benefit.High borosilicate glass has good fire resistance and high physical strength. Compared with ordinary glass, it has no toxic side effects. Its mechanical properties, thermal stability, water resistance, alkali resistance, acid resistance and other properties are greatly improved. Therefore, it can be widely used in various fields such as chemical industry, aerospace, military, family, hospital, etc. It can be made into lamps, tableware, standard plates, telescope pieces, washing machine observation holes, microwave oven dishes, solar water heaters and other products, and has good promotion value and social benefit.

High borosilicate glass is an important material used to make highly durable glass instruments such as beakers and test tubes. Of course, its applications are far more than these. Other applications include vacuum tubes, aquarium heaters, flashlight lenses, professional lighters, pipes, glass ball art, high-quality beverage glassware, solar thermal utilization vacuum tubes, etc., at the same time , has also been used in the aerospace field. For example, the insulation tiles of the space shuttle are also coated with high borosilicate glass.

High borosilicate glass is an important material used to make highly durable glass instruments such as beakers and test tubes. Of course, its applications are far more than these. Other applications include vacuum tubes, aquarium heaters, flashlight lenses, professional lighters, pipes, glass ball art, high-quality beverage glassware, solar thermal utilization vacuum tubes, etc., at the same time , has also been used in the aerospace field. For example, the insulation tiles of the space shuttle are also coated with high borosilicate glass.

Characteristic

High borosilicate glass has a very low thermal expansion coefficient, only about one-third that of ordinary glass. This will reduce the effects of temperature gradient stresses, resulting in greater resistance to fracture. Due to its very small shape deviation, it has become an indispensable material in telescopes and reflectors, and it can also be used to process highly radioactive nuclear waste. Even if the temperature changes suddenly, borosilicate glass is not easily broken. When broken, borosilicate glass develops large cracks rather than shattering into particles. At the same time, high borosilicate glass also has low dispersion and relatively low refractive index.

The linear expansion coefficient of high borosilicate glass G3.3 is (3.3±0.1)×10-6/K, which is a glass with sodium oxide (Na2O), boron oxide (B2O3), and silicon dioxide (SIO2) as its basic components. Plant glass. The content of borosilicate in this glass component is relatively high, namely boron: (12.5~13.5)% and silicon: (78~80)%.

Application areas

Life products

Because high borosilicate glass has a very low thermal expansion coefficient and is resistant to high temperatures, it is ideal for making reflective heat-resistant lampshades for halogen lamps, special glass turntables for microwave ovens, microwave lampshades, stage lighting reflector cups, drum washing machine observation windows, and heat-resistant teapots and cups. , important materials for solar collector tubes, etc.